The Classic collection

The spirit of innovation, creativity and know-how of our teams has been driving the creations of Horus for over 39 years.

The Contemporary collection

Respectful of the historic values of Horus but drawing inspiration from the present, the contemporary collection signs pieces with unique designs.

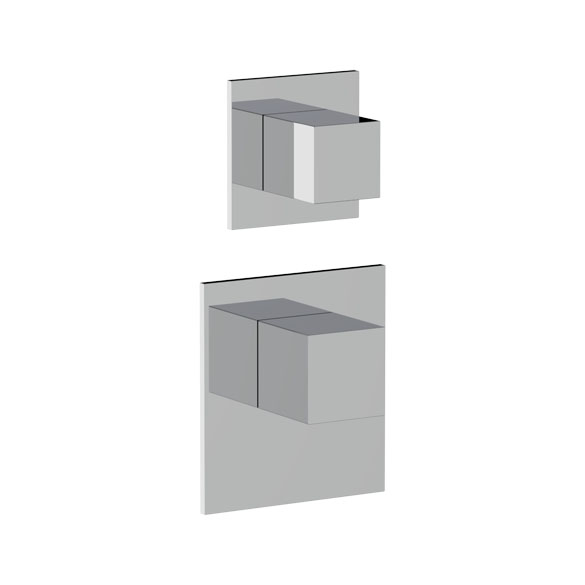

The Concept collection

A resolutely modern and refined design, complete ranges and a new hydrotherapy program.

Our Story

Horus is a symbol of French excellence and stands out for its sharp sense of detail, its use of noble materials and its traditional know-how.

Know-How

Horus has developed a unique expertise and know-how in the manufacturing of high-end faucets and fittings that meet the most demanding quality and environmental standards.

Our achievements

Our collections are inspired by different periods and artistic trends, which has allowed Horus to equip hotels and palaces all over the world for more than 30 years.